Product

Detailed information

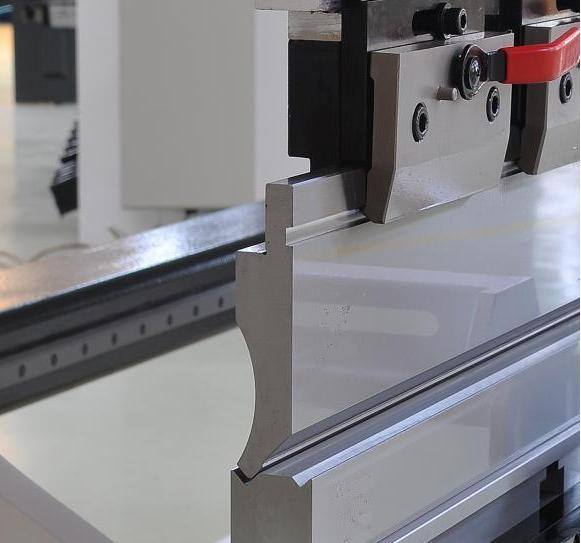

knife blade for shear bending die iron worker tooling

1. Blades quality is reliable and stable;

2. Have a full range of specifications;

3. Can be tailored according to customer requirements;

4. High precision sharp enough, wear-resistant, smooth edge, no burr.

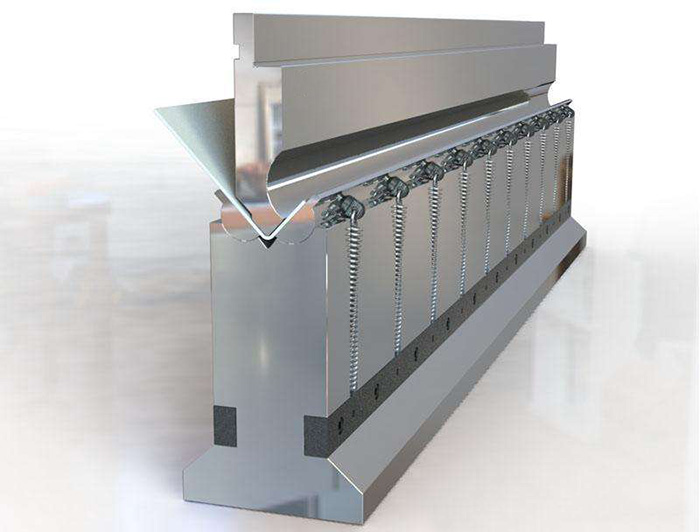

Bending mold details

Material | 42CrMo |

Hardness | 45-50HRC |

Option | Black-antirust |

Standard | Segmented, Arc, International Standard, Three Point, Non-Streaking, Adjustable Groove, Special, etc |

Delivery time | 5 - 10 Days |

Model Number | Large machetes, special custom gooseneck type, straight-edged swords, single V lower die, double-folded upper and lower die; Flanged side avoidance bent upper die, same core 2V rail fixed standard lower die, R round-arc roller fold Bending die, 2V bolt-fixed standard lower die, 1V slot standard lower die, 1V thick panel corner bend lower die, excellent gel lower die, multiple V lower die, various die seats, seamless bending Module, segment differential mode combination, etc |

Bending mold orderin

According to the different requirements of customers, choose the best mold design program, with the fastest time, the best quality to meet customer requirements. In addition, if you have difficulties in selecting a mold, please contact our company. Please provide the following:

1. Detailed shape of the general shape of the finished product and the bent portion (bending radius, inner contour size, tolerance range, etc.)

2. Material, thickness

3. Requirements for scratches (injuries)

4. Machine used for bending (machine model, maximum tonnage, table length)

5. Others, especially need to specify matters.

Upper die interface category:

CNC bending tool segmentation, regular segment specifications are as follows:

Mold section 1

CNC bending on the mold: 100 (left), 10,15,20,40,50,200,300,100 (right) = 835mm

CNC bending lower die: 10, 15, 20, 40, 50, 100, 200, 400 = 835mm

Mold section 2

CNC bending on the mold: 100 (left), 10,15,20,40,50,165,300,100 (right) = 800mm

Production Process:

Down → Forging → Tempering → Finishing → Quenching → Annealing → Conditioning → Coarse Grinding → Finishing → Inspection → Packaging → Factory

Online message

Leave your contact information and we will contact you as soon as possible